Are Adhesives Safe To Use On Food-Grade Materials

December 07, 2024

Adhesives are implemented in a vast program, from the clean circle of relatives' preservation to employer techniques. However, at the same time, as adhesives come into touch with food, it's essential to ensure they may be steady. Food-grade substances communicate with materials that come into direct contact with meals without threatening infection or harm. This consists of packaging, utensils, bins, and unique gadgets that play a characteristic inside the storage or guidance of food. As such, glues used on the materials should fulfill strict protection requirements.

We'll assist you with the security of adhesives on food-grade materials, what to look and where to find them.

Are Adhesives Safe to Use on Food-Grade Materials?

When used correctly, adhesives can be stable on meal-grade materials. However, not all adhesives are created equal, and a few contain chemical substances that are probably unstable if they come into contact with food. It is crucial to use adhesives specially designed for meal-associated programs. These bonding agents are tested to guarantee they meet health prerequisites and don't release risky substances that would taint food.

What Are the Different Types of Adhesives and Their Uses?

Numerous varieties of adhesives can be used on food-grade substances. The most not unusual ones encompass:

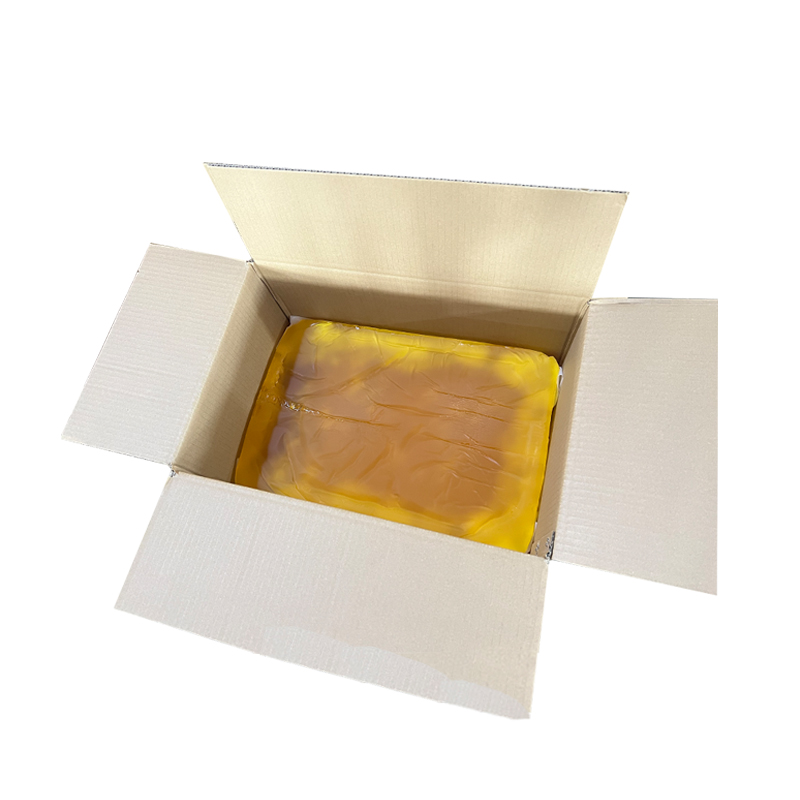

Hot Melt Adhesives:

These adhesives are extensively utilized in meal packaging. They are hot at extraordinarily high temperatures and bond quickly as they cool. Hot adhesives are famous because they offer a strong, durable bond and can be applied to many surfaces, such as plastic, paper, and steel. They are commonly used in packaging for snack baggage, frozen elements, and beverage cartons.

Water-Based Adhesives:

These adhesives use water as the primary solvent and are regularly utilized in packages where minimum chemical exposure is a challenge. They are considered stable for food-grade materials when they meet particular protection requirements. Water-based adhesives are usually used in packaging, labels, and paper products.

Solvent-Based Adhesives:

These adhesives are less common in food-grade programs because they use organic solvents, which can emit fumes or comprise volatile chemical substances. However, in a few enterprise programs, the adhesives may be used if they meet the critical safety necessities and are allowed to treat themselves before touching food.

Pressure-sensitive sealant bond while strain is applied. They are generally used for labels and stickers and are often utilized in meal packaging for labeling or sealing features.

Each adhesive type has specific strengths and packages, and selecting the right one depends on the materials used and the food-grade product's intended use.

How Do You Choose the Best Adhesive for a Specific Material?

Selecting the right adhesive for a specific food-grade material requires considering numerous factors. The kind of cloth, the environment it'll likely be exposed to, and the material's durability all play important roles in this option.

For instance, if you're using food-grade plastic, a warm melt sticky tape might be a fantastic choice due to its brief bonding time and ability to adhere to several surfaces. On the other hand, if you're coping with a paper or cardboard fabric, a water-primarily based, honestly adhesive may work excellent as it cannot affect the advent of the packaging and may be used for light-weight programs.

Durability is a particular consideration. Some adhesives are designed to withstand excessive temperatures, moisture, or freezer conditions. In such instances, deciding on a high-performance epoxy like a warmness-hot adhesive is vital to ensure the bond holds up over time.

Advantages of Using Adhesives Over Mechanical Fasteners

Adhesives offer several benefits over conventional mechanical fasteners, together with screws or rivets, in particular in meal-grade programs. One of the precept blessings is the easy, seamless bond they invent. This removes the hazard of food contamination because of screw exposeds or particular fasteners that could trap food particles.

Another benefit of adhesives is that they provide uniform strain distribution at a few levels inside the bonded vicinity. This is critical in meal packaging, in which even pressure distribution can help prevent leakage or product spoilage.

How Long Does It Take for Adhesive to Dry or Cure?

The drying or curing time of adhesives depends on the adhesive's shape. For example, warm, hot adhesives bond quickly as they cool, generally within seconds to 3 minutes. Water-based adhesives, however, can also take longer to dry, sometimes requiring numerous hours to cure completely.

It's critical to observe the manufacturer's instructions regarding drying times to ensure that the adhesive has cured before the meals-grade fabric is used. Using the adhesive application too early can cause a willing bond, which might cause packaging or packing containers to fail under strain.

Common Problems with Adhesives and How Can They Be Fixed

While adhesives are effective, they may be with their annoying conditions. One unusual problem is adhesive failure, in which the bond doesn't maintain or breaks down through the years. This may be because of incorrect adhesive preference, incorrect software program application, or publicity of harsh environmental situations. To restore this, ensure the right adhesive application is selected for the substances and surroundings and exercise it consistently with the manufacturer's hints.

Another problem is adhesive contamination, in which the permanent adhesive releases risky chemical substances that come into contact with meals. To avoid this, commonly pick adhesives that are probably licensed for meal use and ensure they may be wholly cured earlier than meal touch.

Where to Find Hot Melt Adhesives?

Hot melt adhesives are notably utilized in food packaging and extraordinary meal-associated applications. One of the top providers of top-notch hot adhesives is Iqunzhuoyue. They offer some adhesives that may be notable for food-grade materials, supplying robust, long-lasting bonds that meet safety requirements.

In Wrap Up the adhesives

Adhesives are generally solid enough to be applied to meal-grade materials; however, selecting the correct adhesive for the software program application is essential. Hot adhesives, water-primarily based in reality permanent adhesives, and stress-sensitive glues are the most common sorts used in meal packaging and exclusive food-associated merchandise. Manufacturers can ensure that their merchandise is strong, durable, and robust by choosing an adhesive that meets safety necessities.

FAQs

Are hot melt adhesives steady for food packaging?

Hot adhesives may be steady for meal packaging once they meet meal safety requirements and certifications.

Can I use any adhesive for meal bins?

No, super adhesives, which can be in all likelihood categorized explicitly as food-robust, must be used for meal boxes.

How long does it take for a warm melt adhesive to set?

Hot adhesives are generally set within a few seconds to three minutes as they cool, counting on the software.